4.7 KiB

Executable File

| author | date | title | tags | uuid | |||

|---|---|---|---|---|---|---|---|

| Akbar Rahman | \today | MMME2044 // Seals |

|

ff74e8ad-090d-47eb-b9cc-41ccdefb9a63 |

Function

- used to prevent or limit leakage of fluids or particulates

- keep dirt out

- allow motion

- allow disassembly

Classification of Seals

O-Rings

-

good for static and low speed applications

-

requires interference fit

-

application is codified---use a standard where possible (BS 4518:1982, BS ISO 3601-1~5)

-

sized by internal diameter (ID) and section diameter (A)

-

works by having the rubber o-ring squeezed against the two surfaces

- pre-compression ensures sealing when there is no pressure

Challenger Space Shuttle Disaster

- Space Shuttle Challenger broke apart 73 seconds into flight

- at the low temperatures, the o-rings lost their resilience

- the booster cases distorted during launch

- insufficient groove width in o-ring design

Common Forms of Failure

-

Abrasion---sealing face is worn away. Can be reduced with smoother surfaces, harder materials, better lubricant, and reduced speed

-

Compression set---the sealing face is permanently distorted. Can be solved with more temperature resistant o-rings

-

Installation damage---can be avoided with chamfers and blending radii

-

Extrusion---the o-ring is forced into the sealing clearence. can be avoided with:

- smaller clearances < 0.13 mm;

- harder material

- different cross section

- backup rings---come in a range of shapes and sizes (BS 5106:1988)

-

Spiral damage---o-ring is twisted and leaks. can be avoided with:

- lower reciprocating speed

- harder material

- different cross sections (e.g. quadrant seals, which have a x-shaped section)

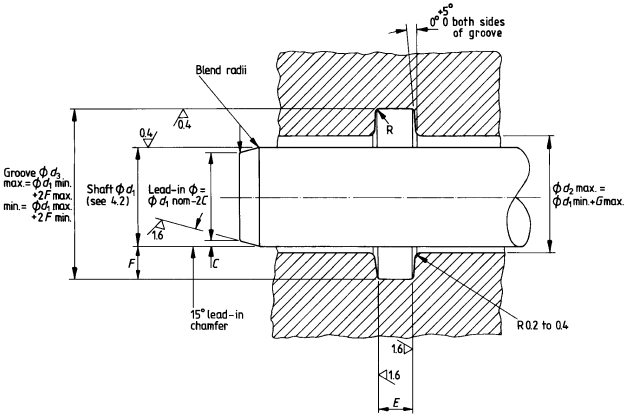

Groove Dimensions

- up to 100 bar for static loading

- up to 14 bar & 3.8 m/s for dynamic loading

i don't know when this is the case but it just says this in the [lecture slides](./lecture_slides/Lecture 6 Seals_v1.0.pdf) (and i haven't watched the lecture yet)

- $F$---radial depth

- $E$---groove width

- $G$---total clearance

- $C$---lead-in chamfer

- $R$---radius

Groove in Cylinder

Groove in Piston

Example of a Dimensions Table

O-Ring Properties

| Material | Hardness (Shore A) | Temperature Range ($^{\circ}$C) | Uses |

|---|---|---|---|

| Nitrile rubber | 70 | -30 to 110 | general purpose, fuel, oils, water |

| Silicone | 70 | -60 to 200 | medical, body fluid resistant, low temp, alcohol, oxygen |

| Viton (fluorocarbon) | 85 | -20 to 200 | high temperature, extreme chemicals |

| Polyurethane | 95 | -30 to 110 | high temps, oil, gas, hydraulics, good wear |

Shore A context:

| Item | Hardness (Shore A) |

|---|---|

| Rubber band | 20 |

| Pencil rubber | 40 |

| Tire tread | 70 |

| Shoe heel | 80 |

Gaskets

- a material or combination of materials clamped between two separable members to form a joint

Gasket Anatomy

- Base material---a compliant element such as cork, cellulose, or a fibre

- Binders---temperature and chemical resistant material such as rubber, elastomers, and resins

- Fillers---fill voids in base material. usually rubbers, elastomers, or resins

- Reinforcements---prevents distortion. usually a metal or fabric core

Seals in Rotating Shafts

- low pressure and low temperature---o rings, radial lip seals, axial lip seals

- high pressure---high performance lip seals, mechanical seals

- high temperature---labrynth seals

O-Rings

- o-rings can be used in dynamic applications

- friction is high but sealing is good within operating range (14 bar, 3.8 m/s)

- surface roughness must not exceed 0.4 mm Ra, should be around 0.1 mm Ra

- spiral and abrasion are main failure modes, if installed correctly

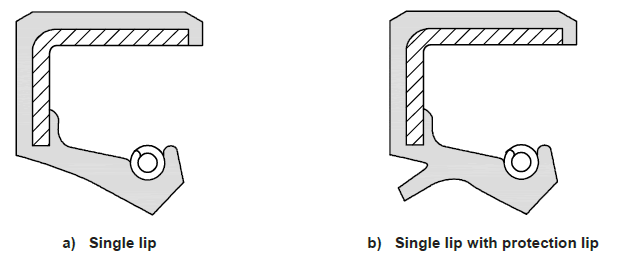

Radial Lip Seal Anatomy

- low pressure---0.3-0.6 bar, up to 7 bar with backing plate

- moderate speed---up to 16 m/s

- high temperature

- normal environmental conditions

- slight leakage permitted

- normally made of nitrile rubber compounds